|

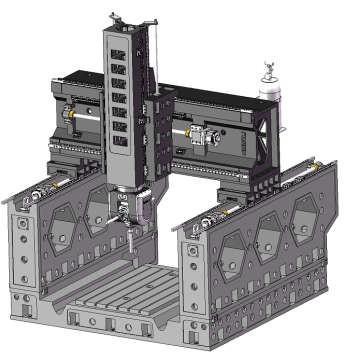

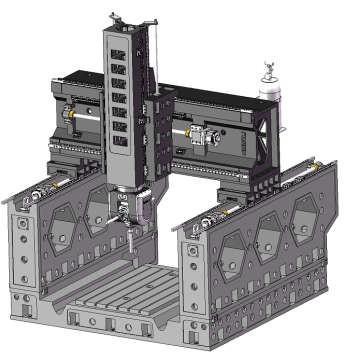

It is a new-age CNC machine tool with innovative framework design on the basis of extensively absorbing and assimilating CNC machine tool manufacturing technologies, combined with the practical technical requirements of users. It has the advanced level of similar products and is an advanced equipment with high efficiency, high precision and high performance.

This machine tool can be widely used in the fields of automobile, shipbuilding, locomotive, military industry, aerospace, machine tools, molds and other mechanical equipment manufacturing industries. CNC machining of precision parts, one-time clamping of the workpiece can complete milling, boring, drilling, reaming, tapping Silk and other processes.

MACHINE STRUCTURE

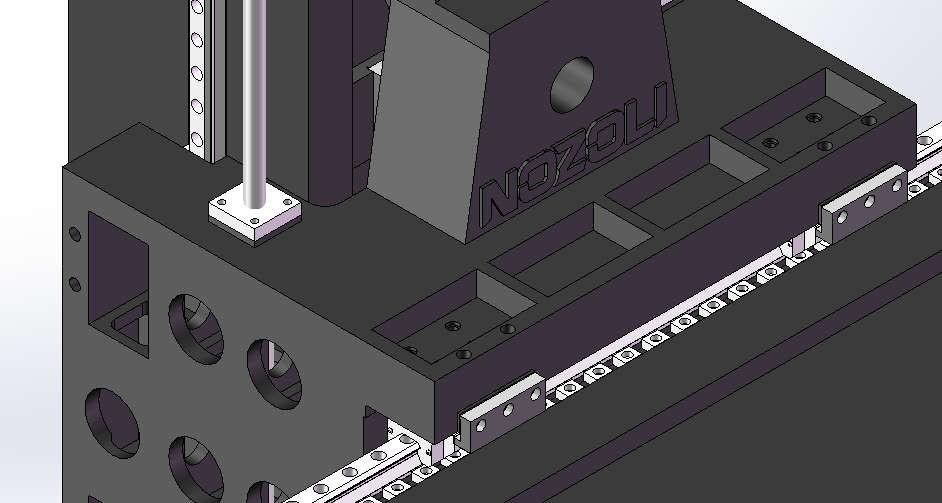

The high-speed bridge-type five-axis gantry machine tool bed, column, beam, slide seat, and ram are cast parts to ensure sufficient processing rigidity and adapt to the characteristics of the workpiece. It is a thin-walled welded part and the workpiece is long. This machine tool has a high cutting speed. The cutting condition is good, the force on the tool and the workpiece is small, the metal removal rate is high, the stress generated by the workpiece cutting process is small, and the surface quality of the workpiece is good; at the same time, the fast moving speed is fast, and the auxiliary time required is less. It is equipped with a double-arm five-axis The head realizes one-time clamping, multi-angle processing, curved surface processing and streamline processing. The whole machine is surrounded by protection, the machine tool has automatic chip removal function, and is equipped with water cooling function. The machine tool is beautiful in shape, easy to operate and maintain.

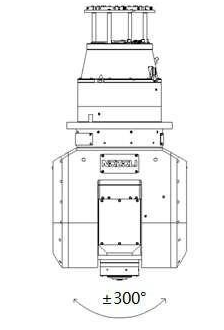

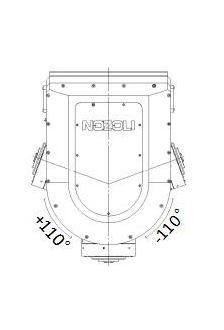

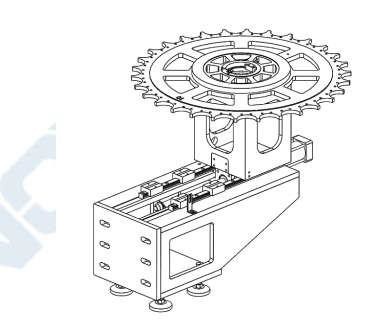

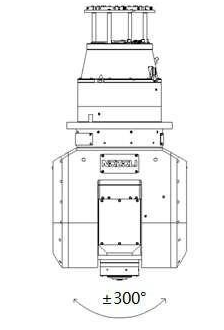

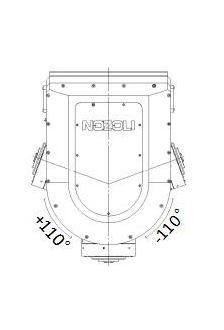

FIVE-AXIS FIVE-LINKAGE HEAD

(1) The two rotary motions of the five-axis five-linkage head are the A axis and the C axis respectively. The A-axis is ±110°, and the C-axis is ±300°. The main power source is a permanent magnet high-torque torque motor, and the angle encoder guarantees accuracy. Both are small in size and compact in structure and high in flexibility. , the combination of the three achieves full rotation in 3D space, which perfectly solves the multiple debuggingand clamping required for repositioning the workpiece at complex angles, and reduces positioning errors. It is suitable for products with complex shapes and high precision requirements. It can complete the processing of curved surfaces at all angles in one clamping and improve production efficiency. Personalized configuration, high-precision modular design, to achieve rich expansion functions.

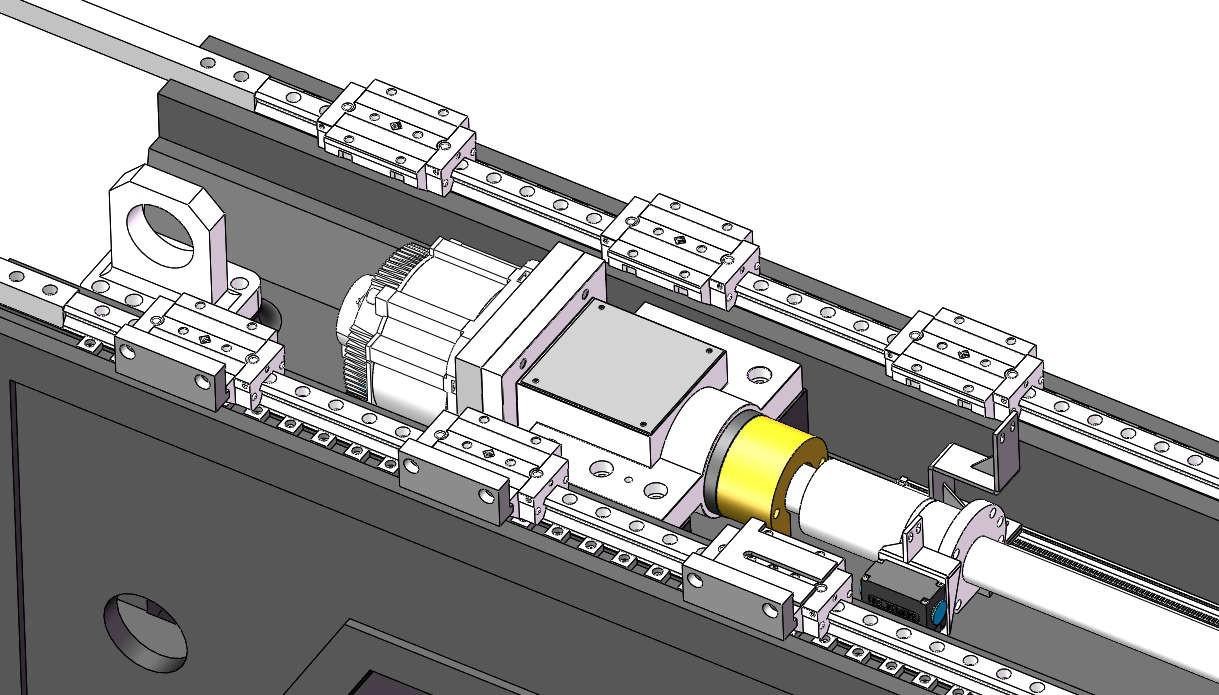

(X, Y, Z) axis technical performance characteristics

X-axis

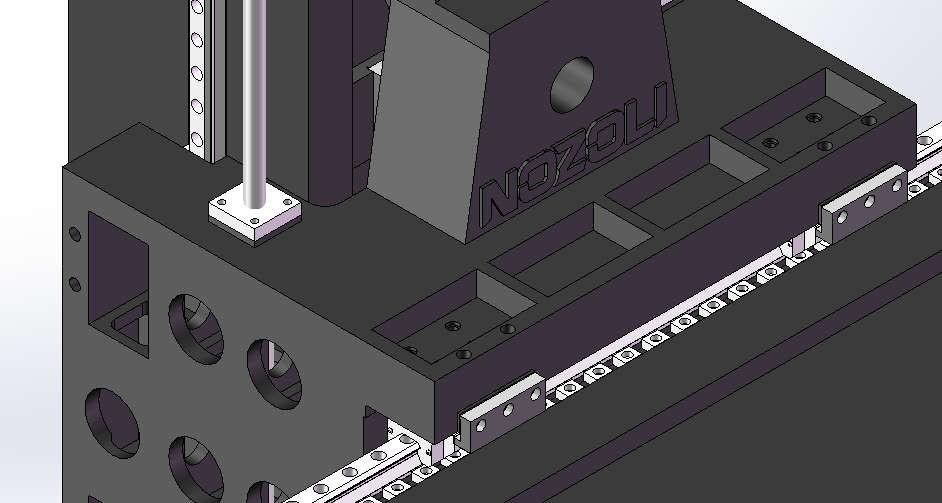

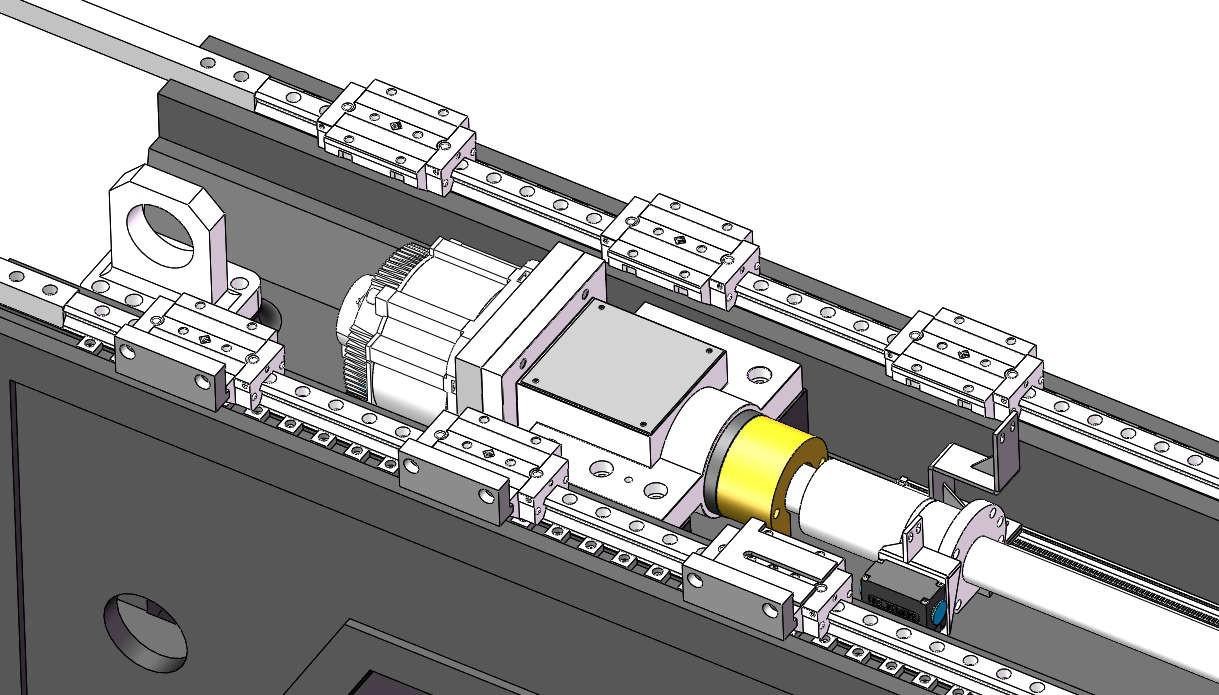

(1) X guide rail form: The column is equipped with four 35mm heavy-duty roller linear guide rails. Can meet the high rigidity of the gantry frame requirements, and can meet the technical advantages of small friction coefficient, fast moving speed and long service life; lubrication method: oil lubrication;

(2) X-axis transmission: AC servo motor is used to drive the precision ball screw with a diameter of 50mm to rotate after speed up and down, so as to realize the left and right feeding of the slide plate; lubrication method: oil lubrication; screw brand: Taiwan Shangyin or the same level brand;

(3) Equipped with double high-precision full-closed-loop grating rulers; grating ruler brand: Spain FAGOR or the same level brand;

(4) Guide rail protection: the leather cavity shield is used for protection to prevent foreign matter from entering and polluting the guide rail. The protective cover has a beautiful appearance and a sound structure.

Y-axis

(1) Guide rail form: The Y axis adopts two 55 heavy-duty roller linear guide rails, which are used as the guide and guide for the horizontal movement of the slide plate. Load bearing track. It can meet the technical requirements of high-speed finishing and low- speed heavy cutting. Lubrication method: oil lubrication.

(2) Y-axis transmission: AC servo motor is used to drive the precision ball screw with a diameter of 50mm to rotate after the speed is increased and decreased, so as to realize the left and right feeding of the slide plate. Lubrication method: oil lubrication.

(3) Equipped with high-precision full-closed-loop grating ruler; grating ruler brand: Spain FAGOR or the same level brand;

(4) Guide rail protection: the leather cavity shield is used for protection to prevent foreign matter from entering and polluting the guide rail. The protective cover has a beautiful appearance and a reasonable structure.

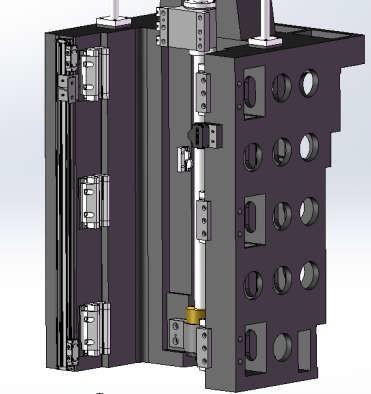

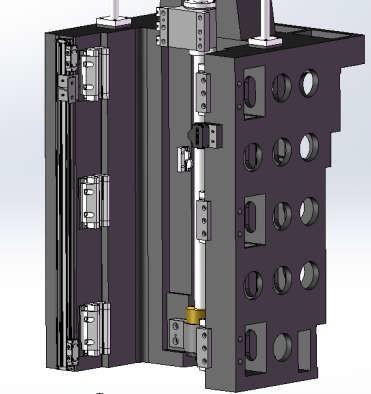

Z-axis

(1) Guideway form: The Z axis adopts two 45 heavy-duty roller linear guideways, which are used as the guide and load-bearing for the ram to move up and down Track; Lubrication method: oil lubrication;

(2) Z-axis transmission: AC servo motor is used to drive the precision ball screw with a diameter of 50mm to rotate after speed up and down, so as to realize the vertical feed of the Z axis; lubrication method: oil lubrication;

(3) Equipped with double high-precision full-closed-loop grating rulers; grating ruler brand: Spain FAGOR or the same level brand.

FIVE-AXIS SYSTEM: HEIDENHAIN SYSTEM TNC640

|

|

The Dynamic Efficiency package is tailored to the requirements of rough machining. The different functions offer great potential for optimizing process reliability, processing and service life. This makes production more efficient, stable and predictable.

Dynamic Accuracy includes functions that improve the path accuracy of machine tools, even at high feeds and complex movements. As a result, precision components with short machining times and no manual rework can be produced efficiently.

Smart solutions for the highest demands

24 control loops (22 with functional safety functions), 4 of them as spindles Version with touch screen for multi-touch operation Milling, 5-axis milling

Simple programming in plain text from HEIDENHAIN or according to DIN/ISO Extensive cycle packages for machining and probing systems

High-end performance for flawless surfaces and highest precision Low record processing time (0.5 ms)

Dynamic collision monitoring for increased safety

HYDRAULIC AND LUBRICATION SYSTEM

Lubrication system; this machine tool adopts group independent oil supply technology

(1) X, Y, Z-axis guide rails, lead screws, and racks adopt a set of independent automatic oil supply and lubrication systems. The screw bearings are grease lubricated.

(2) Spindle oil-air lubrication/automatic thin oil lubrication is a timing and quantitative automatic method, the action is automatically controlled by the numerical control system, and can detect and alarm. Lubricating pump brand optional: SKF oil-air lubrication/Proton or equivalent brand

HYDRAULIC SYSTEM

(1) This machine tool has an independent hydraulic system.

(2) The machine tool is equipped with a separate hydraulic pump station. The hydraulic system is equipped with multiple safety monitoring devices such as oil level alarm, temperature alarm, backflow blockage alarm, and minimum working pressure alarm to ensure that the machine tool can work under various safety conditions. Improve operator safety protection.

CUTTING COOLING SYSTEM

(1) Cutting external cooling system, at the nose of the spindle, closer to the tool, more perfect cooling processing point, effectively controlling the cutting temperature, so that the processing can meet the requirements of higher precision.

(2) Separate cooling water to cool the five-axis five-linkage head and the main shaft

CHIP REMOVAL SYSTEM

This machine tool adopts twin-screw chip removal, a chain chip removal device and a chip receiving car to form a chip removal system, which facilitates the cleaning of iron chips.

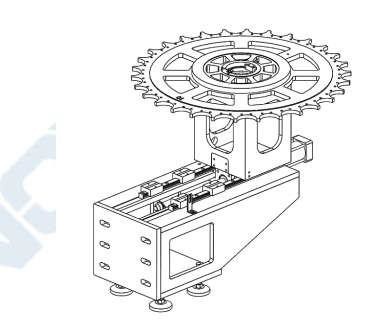

Horizontal tool magazine-two-way forward and reverse arbitrary style-24/32T tool magazine.

|

|

OPTIONAL

F230 non-contact laser tool setting can measure the maximum diameter ∅170 Brand: Renishaw or equivalent brand

|

|

Online detection head (optional)

RMP60 is an ultra-small workpiece probe using radio signal transmission, which can be used for automatic workpiece alignment and in-sequence measurement on machining centers, including five-axis machine tools.

The combination of the traditional Renishaw mechanical resistance probe mechanism in RMP60 and the unique and reliable frequency modulation transmission protocol makes it an ideal choice for machining workshops. The alignment of workpieces and fixtures ensures the accuracy of machining benchmarks and reduces manual alignment time.

|

|

Full closed loop grating ruler

X, Y, and Z axes adopt HEIDENHAIN (or equivalent) position detection grating ruler or encoder full-closed loop control; the grating ruler of each axis should have anti-fouling function to avoid the intrusion of oil and dust.

|

|

Machine tool safety protection and appearance

All CNC machine tools in our factory adopt the standard "GB/T15760-2004 Metal Cutting Machine Tool Safety Protection General Technical Conditions".

In the transmission system of X, Y, Z, and each axis of the machine tool, electrical limiters are set to keep the machine tool working in a safe and reliable state, and ensure the absolute safety of the normal work of the operator.

The appearance design of the machine tool can be made according to the customer's requirements. During the production process, the customer can participate in the production

Machine tool control and electrical parts

Working environment conditions of the control device

Working power supply: three-phase AC 380V±10; 50HZ±2 . If the power supply fluctuates greatly, it is recommended to configure an automatic AC voltage stabilizing device.

Ambient temperature: -10℃~45℃. Relative humidity: ≤85

Machine Parameters

| ITEMS | UNIT | PARAMETERS |

| 3 axis travel | X-axis travel (table moves back and forth) | mm | 2200 |

| Y-axis travel (carriage moves left and right) | mm | 1600 |

| Z-axis travel (ram moves up and down) | mm | 1000 |

| Gantry span | mm | 2300 |

| Distance from spindle end face to worktable surface | mm | 0-1000 |

| worktable | working desk size | mm | 1200×1800 |

| weight capacity | tons/square meter | 18 |

| T-slots Quantity/Size/Spacing | ― | 6-22x180 |

| spindle | Spindle speed | r/min | 20000 |

| main motor power | kW | 20/25 |

| Maximum torque | Nm | 35 |

| Spindle taper | ― | HSK-63A |

| A axis | Rated Torque/Maximum Torque | Nm | 240/439 |

| clamping torque | Nm | 1200 |

| swing angle | ― | ±110° |

| positioning accuracy | ― | ±5″ |

| C axis | Rated Torque/Maximum Torque | Nm | 361/614 |

| clamping torque | Nm | 1680 |

| swing angle | ― | ±300° |

| positioning accuracy | ― | ±3.5″ |

| X, Y, Z rapid traverse speed | m/min | 24/24/24 |

| Accuracy | X, Y, Z positioning accuracy | mm | 0.025/0.02/0.015 |

| X, Y, Z repeat positioning accuracy | mm | 0.013/0.01/0.008 |

| weight approx. | t | 27 |

| | Floor area: length, width and height | m | m/min | 5×6m×5m |

|