The five-axis machining center adopts a stable closed gantry structure and is equipped with a standard electric spindle, a two-axis direct-drive CNC turntable and a horizontal chain servo tool magazine. It can realize high-speed, high-precision and efficient machining of complex parts. It is widely used in new manufacturing of energy vehicles, aviation integral blisks, steam turbines impellers, molds and other products.

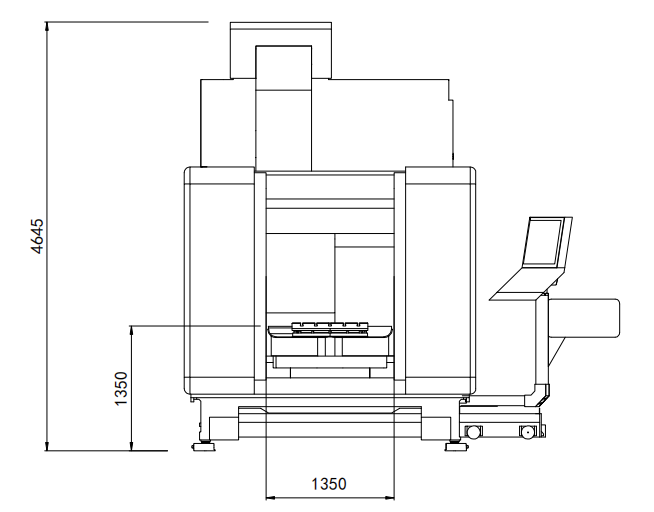

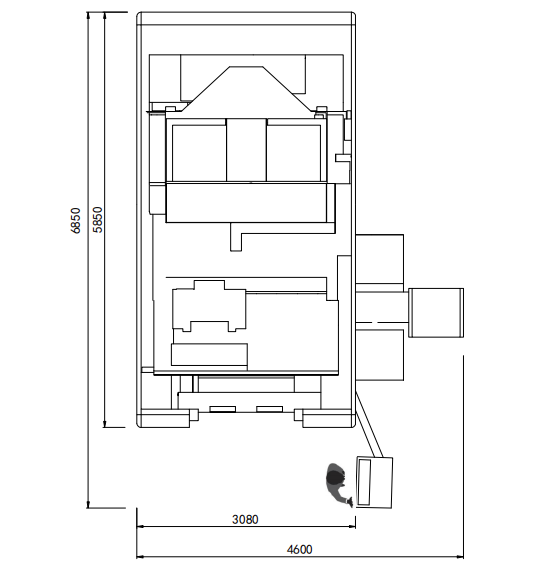

1. Overall layout of the machine

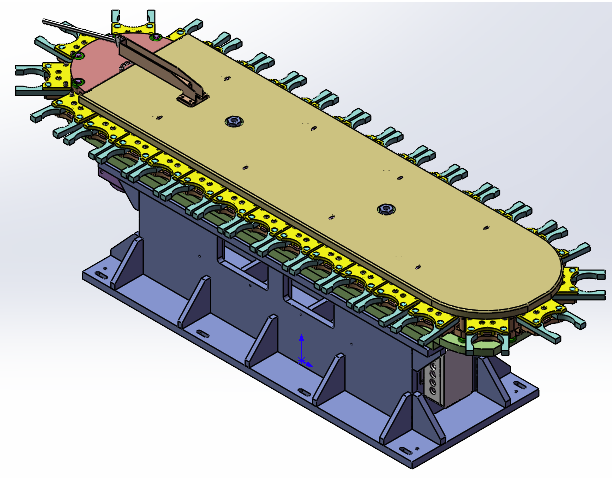

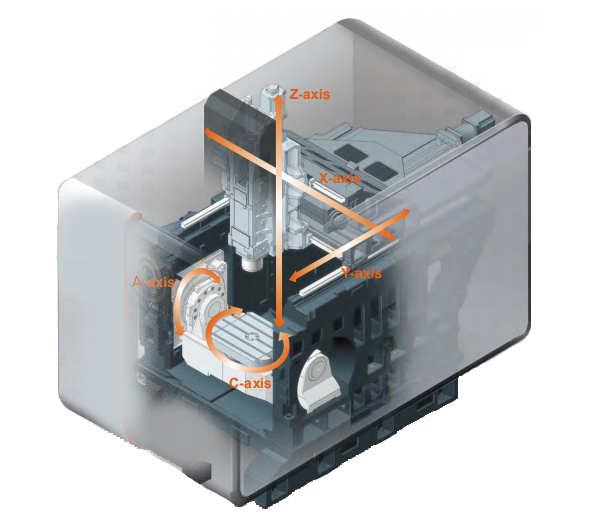

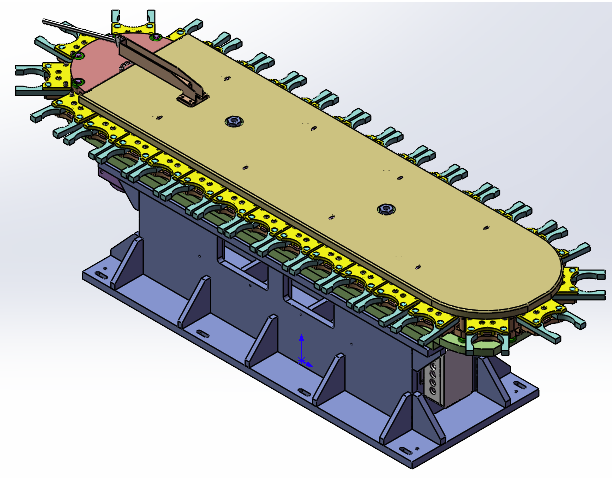

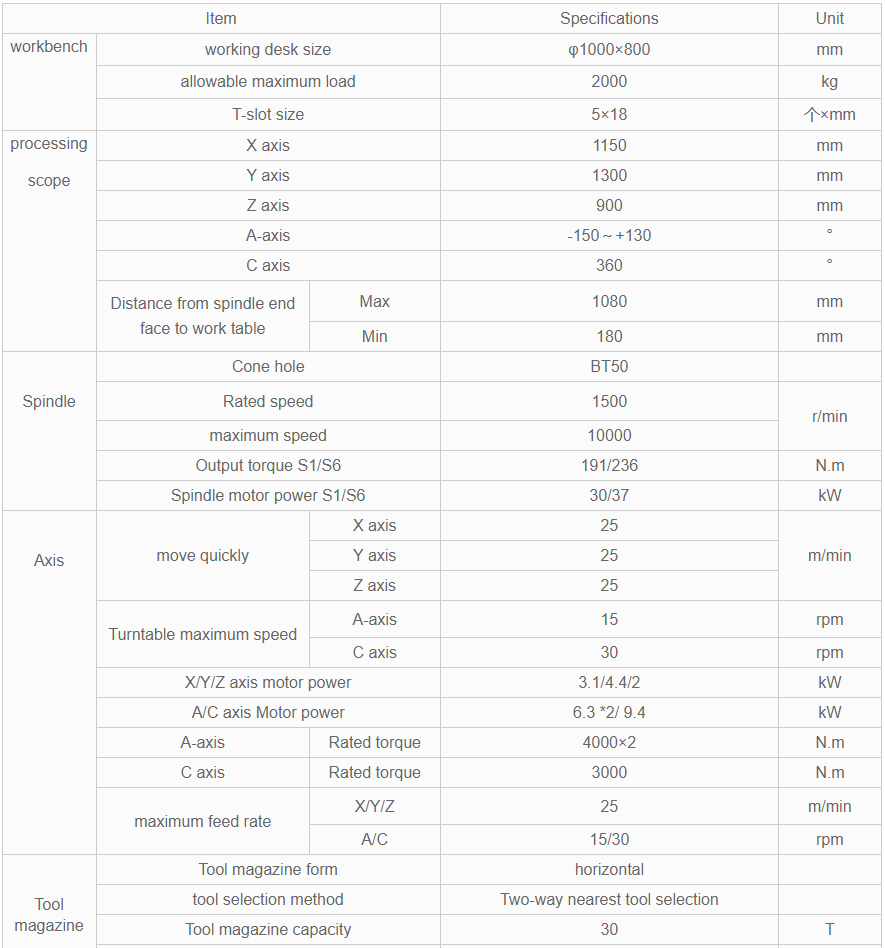

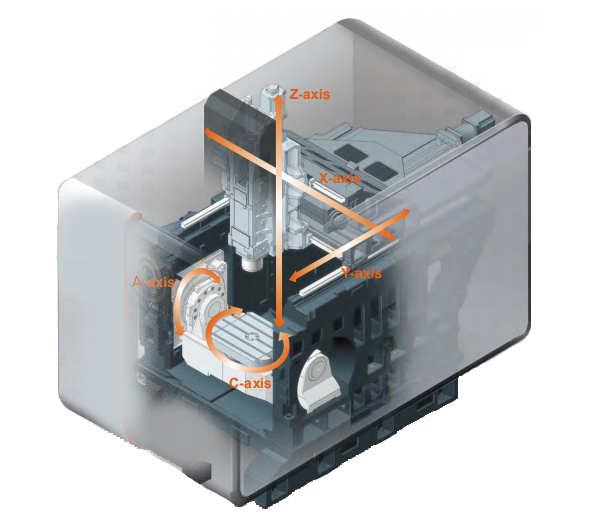

The OM – 1000 five-axis machining center adopts a stable gantry structure, the column is fixed on the base, the beam moves longitudinally along the column (Y direction), the slide plate moves laterally along the beam (X direction), and the headstock moves vertically along the slide plate (Z direction). The workbench adopts the self-developed direct-drive cradle structure, and various performance indicators have reached the international advanced level.

The OM – 1000 five-axis machining center adopts a stable gantry structure, the column is fixed on the base, the beam moves longitudinally along the column (Y direction), the slide plate moves laterally along the beam (X direction), and the headstock moves vertically along the slide plate (Z direction). The workbench adopts the self-developed direct-drive cradle structure, and various performance indicators have reached the international advanced level.

2. Feeding system

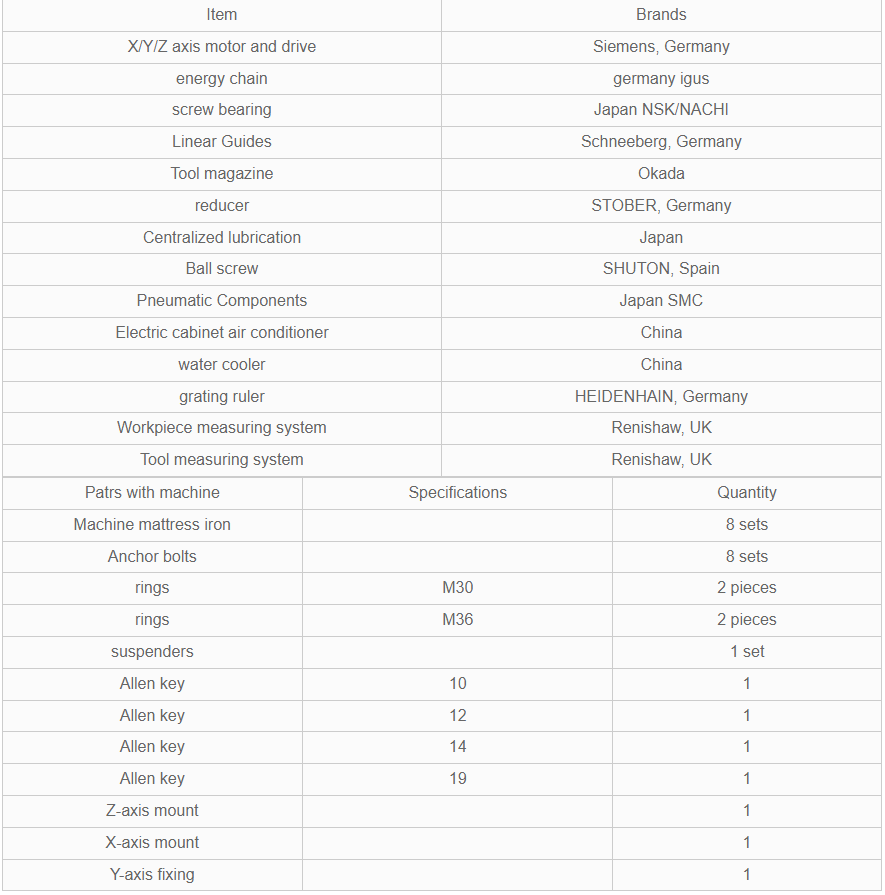

The X, Y, Z axes adopt ultra-high rigidity, high-precision roller linear guides and high-performance ball screws, with low dynamic and static friction, high sensitivity, low vibration at high speed, no creep at low speed, high positioning accuracy, and excellent servo drive performance. X, Y, Z axis servo motors are connected with high precision ball screws through precision reducers, with flexible feeding, accurate positioning and high transmission precision. The Z-axis servo motor has a brake function. In the case of power failure, it can automatically hold the brake to hold the motor shaft tightly so that it cannot rotate, which plays a role in safety protection.

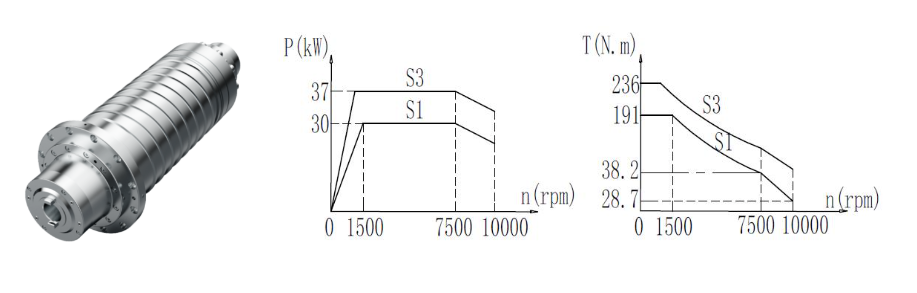

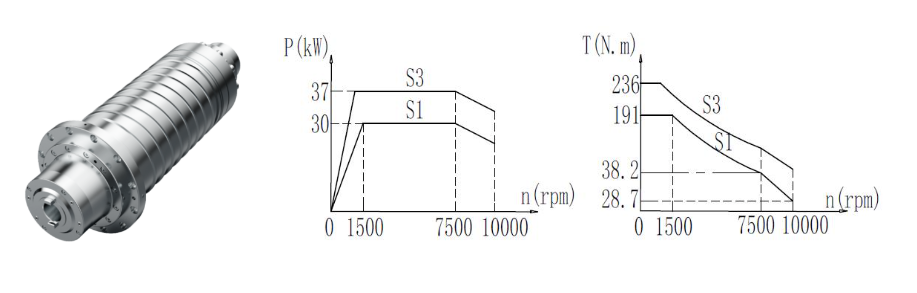

3. Electric spindle

The motorized spindle adopts the self-developed BT50 motorized spindle (HSKA100 motorized spindle is optional), and the end is equipped with a ring spray joint to cool the tool. It has the advantages of high speed, high precision, high dynamic response, etc., and can realize stepless speed regulation , built-in high-precision encoder, can achieve directional accurate stop and rigid tapping.

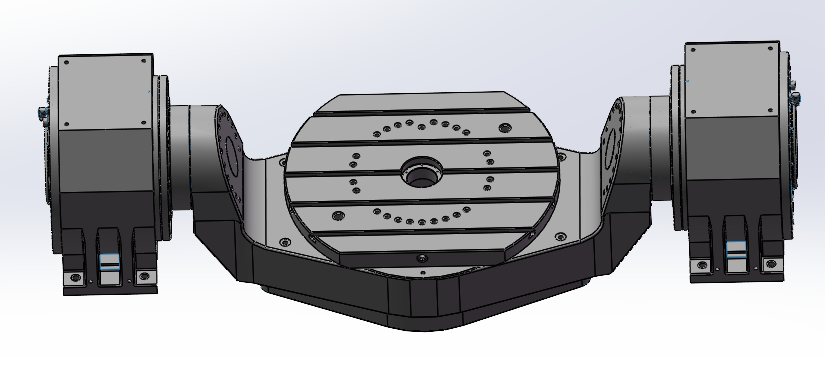

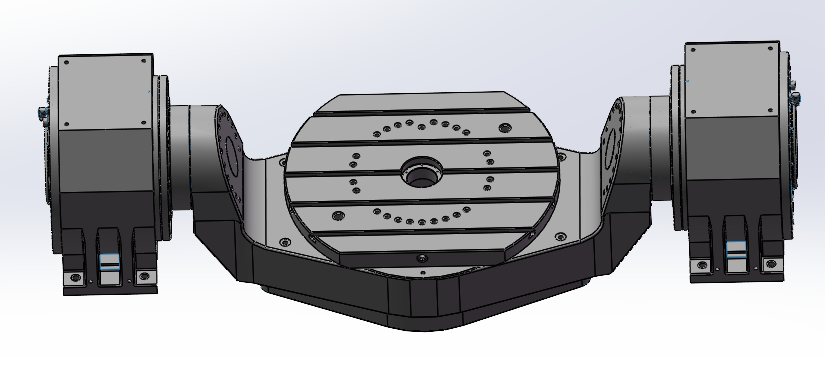

4. Turntable

The self-developed dual-axis direct-drive cradle turntable is equipped with a high-precision absolute encoder and is cooled by a water cooler at a constant temperature. It has the advantages of high rigidity, high precision, and high dynamic response. The worktable adopts 5-18 mm radial T-slots, and the allowable load is 2000 kg (evenly distributed).

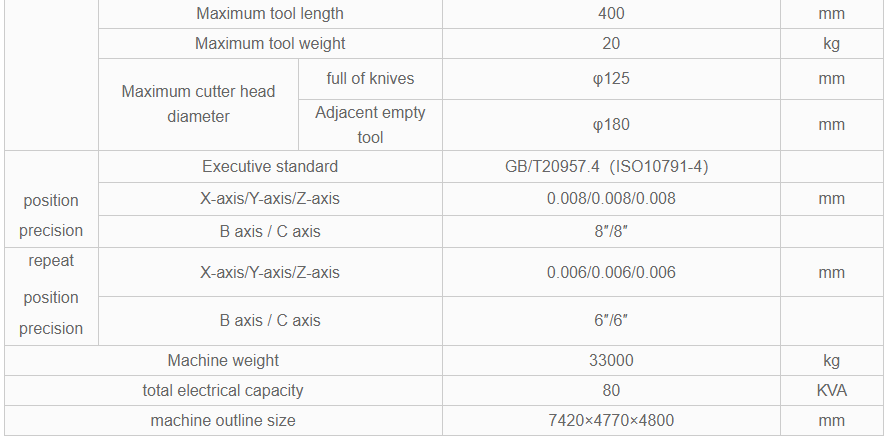

5. Tool magazine

The tool magazine adopts BT50 horizontal chain servo tool magazine, which can accommodate 30 tools.

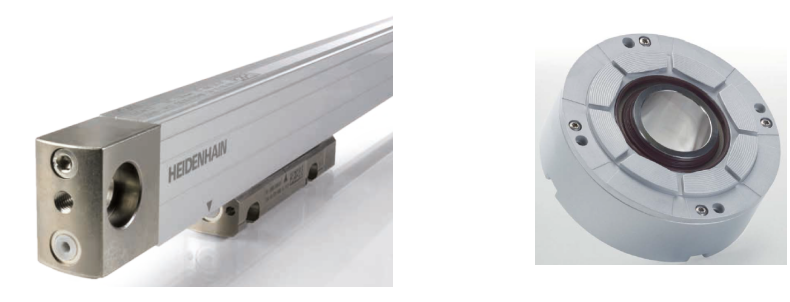

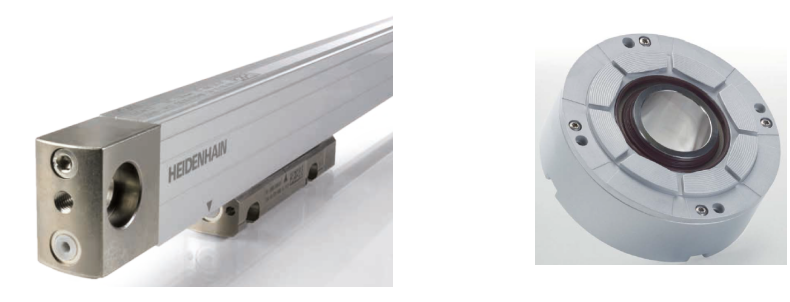

6. Fully closed loop feedback system

X, Y, Z linear axes are equipped with HEIDENHAIN LC195S absolute value grating ruler; A and C rotary tables are equipped with HEIDENHAIN RCN2310 absolute value angle encoders to realize full closed-loop feedback of 5 feed axes, ensuring the machine has high precision and high precision retention.

7. Cooling and pneumatic system

Equipped with large flow cooling pump and water tank to provide sufficient cooling of the tools and workpieces. The headstock end face is equipped with cooling nozzles, which can be controlled by M code or control panel. Equipped with a water cooler for constant temperature cooling, to ensure that the electric spindle and the direct drive turntable are in good working condition and can run efficiently for a long time. The pneumatic system adopts pneumatic components for filtering, and realizes the functions of cleaning and blowing the taper hole of the spindle, protecting the air seal of the spindle bearing, and blowing and cleaning the grating ruler.

8. Centralized lubrication system

The slide block of the guide rail and the nut of the ball screw are all lubricated with thin grease, and the lubrication is provided regularly and quantitatively to ensure the precision and stability of the ball screw and the guide rail.

9. Oil and gas lubrication system

The electric spindle is equipped with imported oil and gas lubrication device, which can fully lubricate and cool the spindle. The sensor can provide abnormal lubrication alarm, which can effectively ensure the spindle can work stably at high speed for a long time.

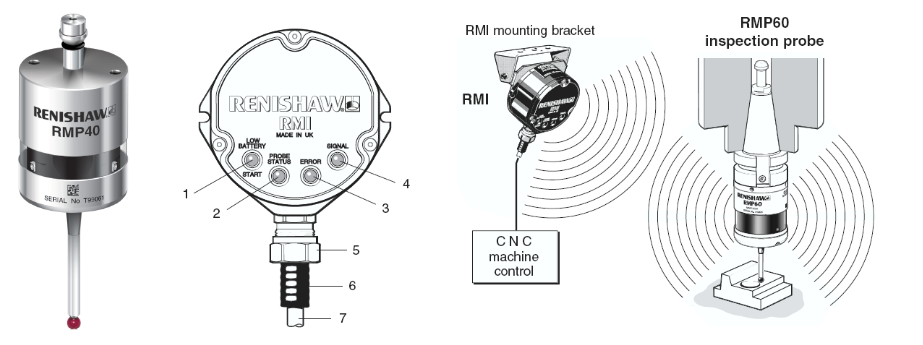

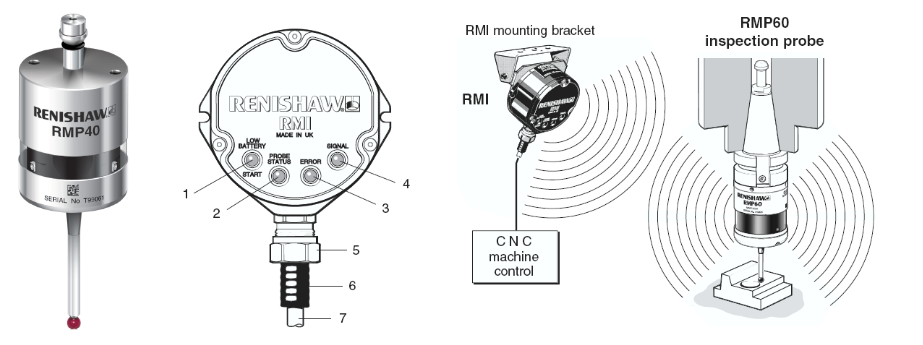

10. Workpiece measuring system

The machine is equipped with Renishaw RMP60 radio probe, used in conjunction with the RMI receiver, the working frequency is 2400 MHz to 2483.5 MHz, the measurement one-way repeatability is less than or equal to 1um (480 mm/min measurement speed, using a 50 mm stylus), and the applicable working temperature is 5°C to 55°C.

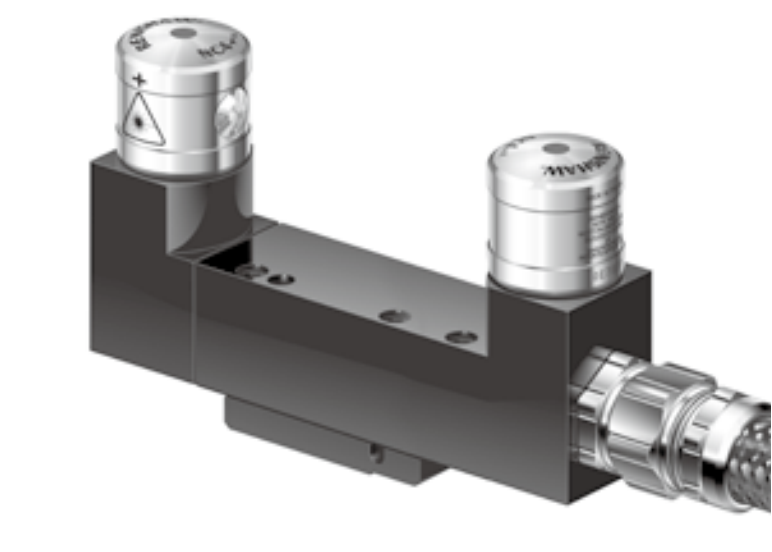

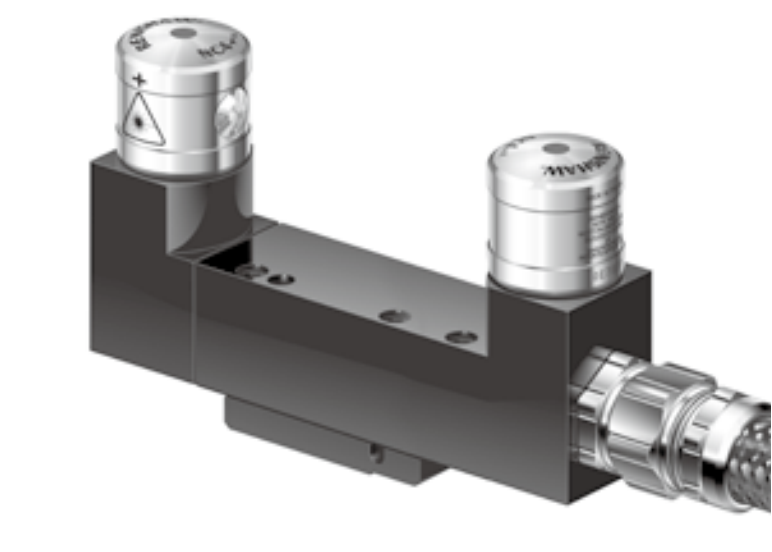

11. Tool measuring system

The machine is equipped with Renishaw NC4 laser tool setter, the measurement repeatability is ±0.1um, and the working temperature is 5°C to 50°C.

12. Five-axis precision calibration function

The machine is equipped with Renishaw's AxiSet Check-Up Rotary Axis Line Checker kit, paired with the workpiece measurement system RMP60, enabling machine users to quickly and accurately check the condition of rotary axes and identify problems caused by temperature and humidity changes, machine collisions or wear and tear problems, can quickly adjust and locate performance checks, benchmark and monitor how complex machines change over time.

13. Machine protection

The machine adopts a fully enclosed overall protective cover that meets safety standards to prevent splashing of coolant and chips, ensure safe operation, and have a pleasant appearance. The X-direction of the machine is equipped with an armored protective cover, which can effectively protect the guide rail and ball screw.

14. Machine working conditions

(1) Power supply: 380V±10% 50HZ±1HZ three-phase alternating current

(2) Ambient temperature: 5℃-40℃

(3) Best temperature: 20℃±2℃

(4) Relative humidity: 20-75%

(5) Air source pressure: 6±1 bar

(6) Air source flow: 500 L/min

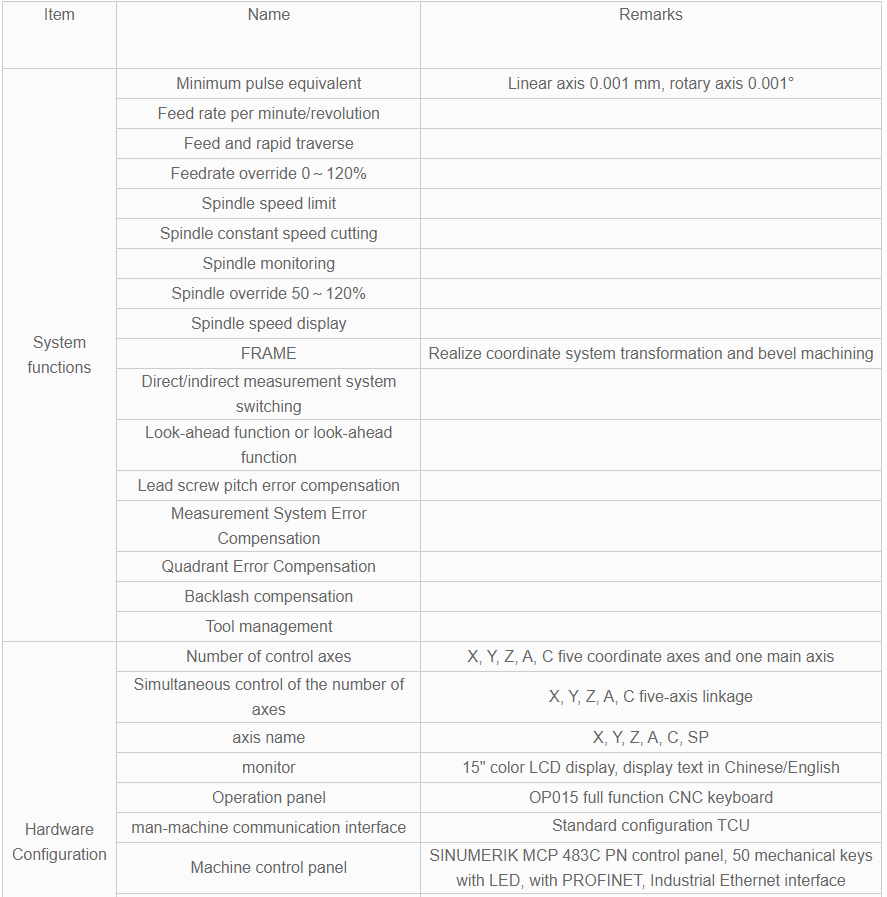

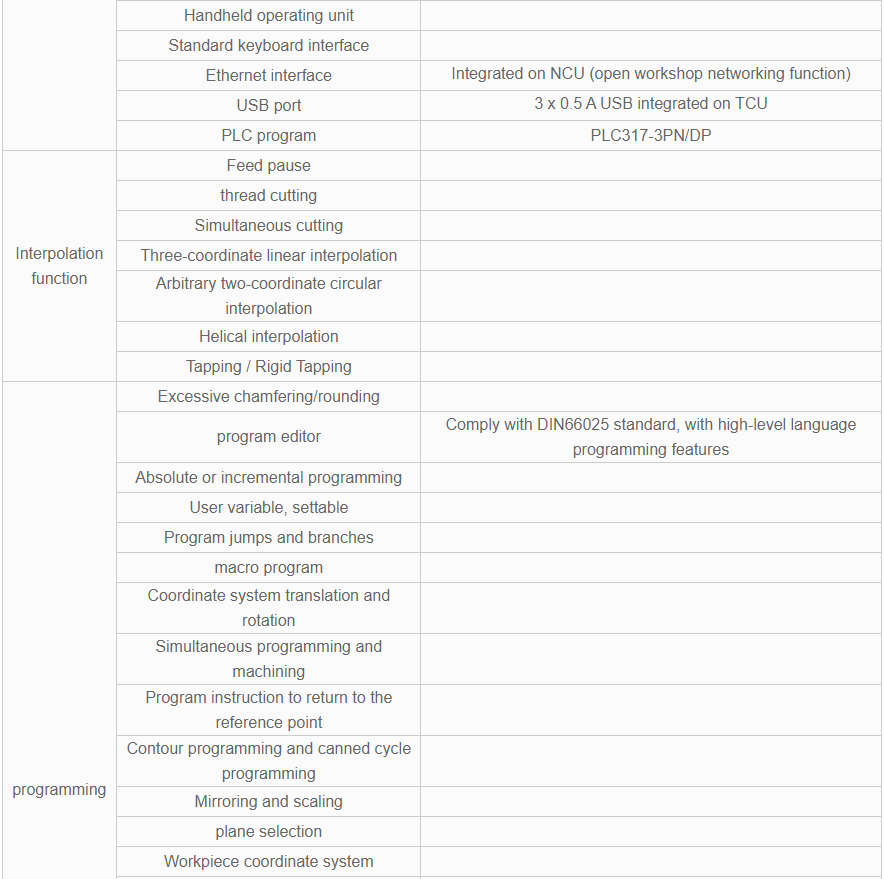

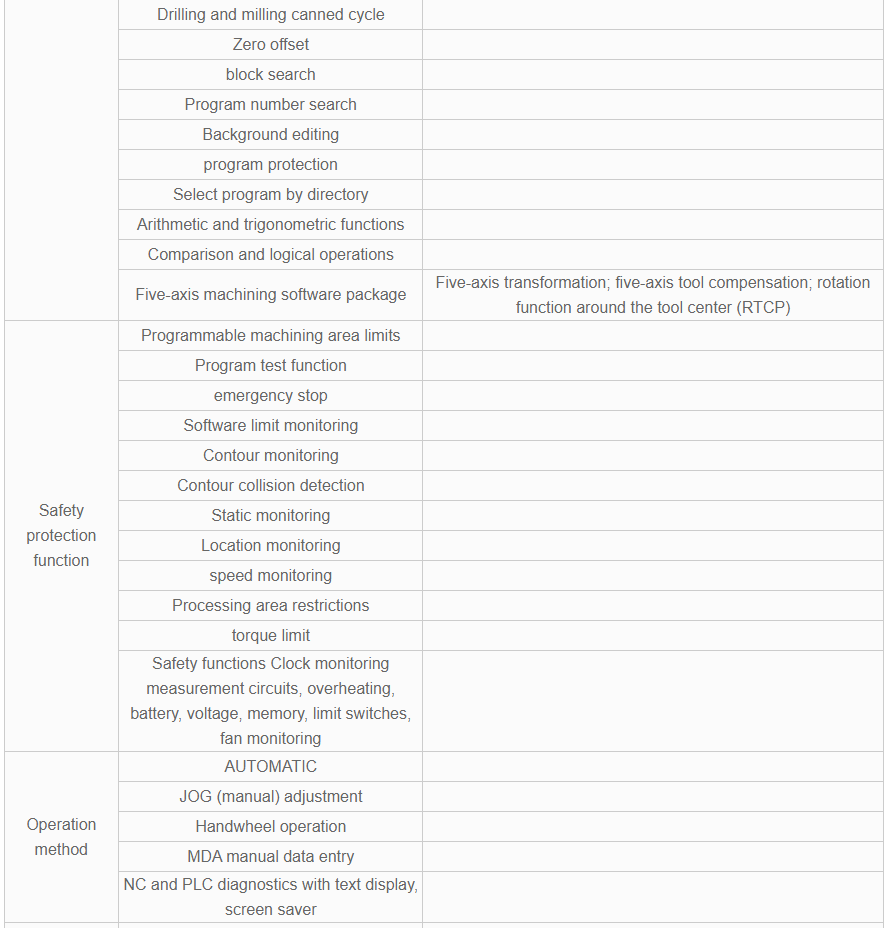

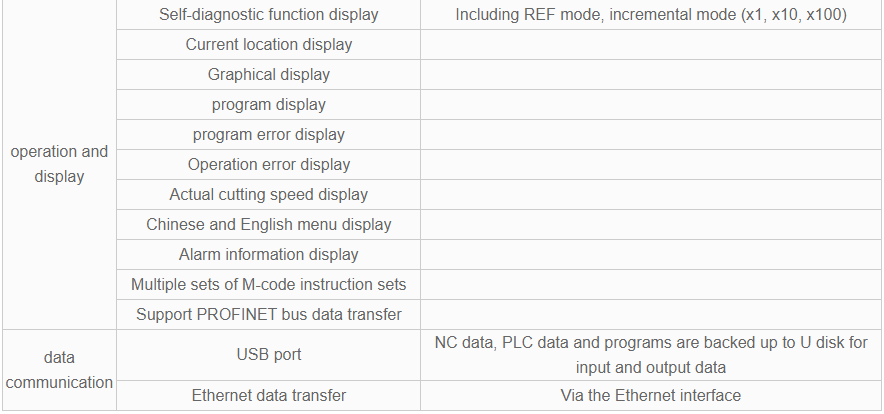

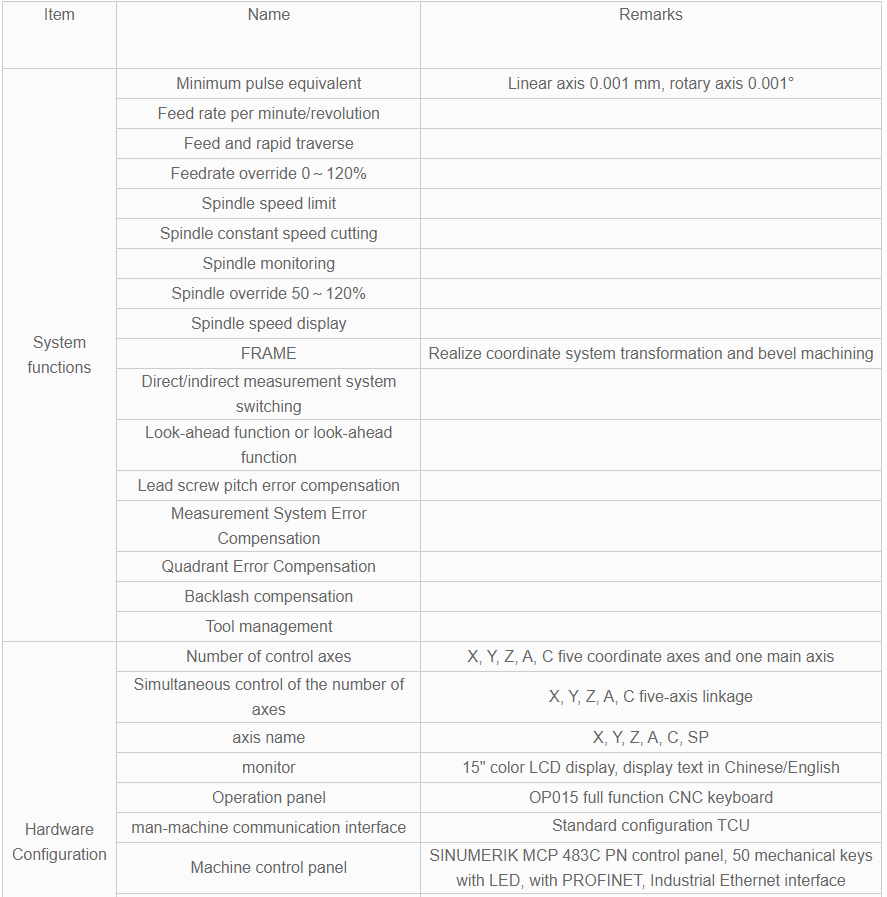

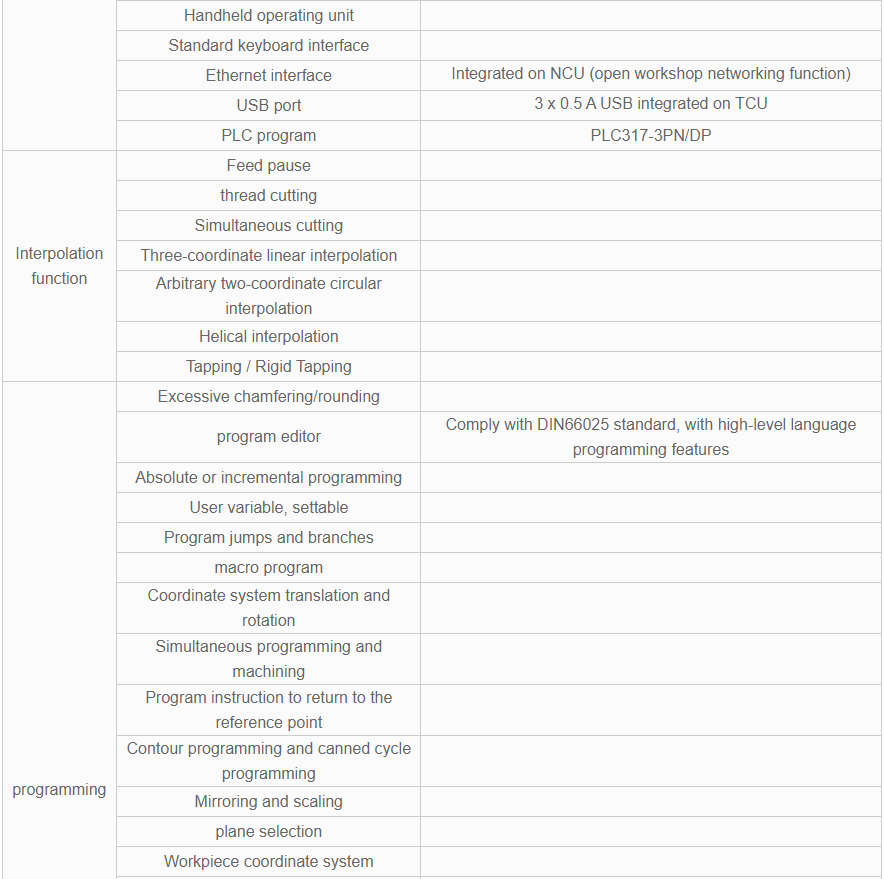

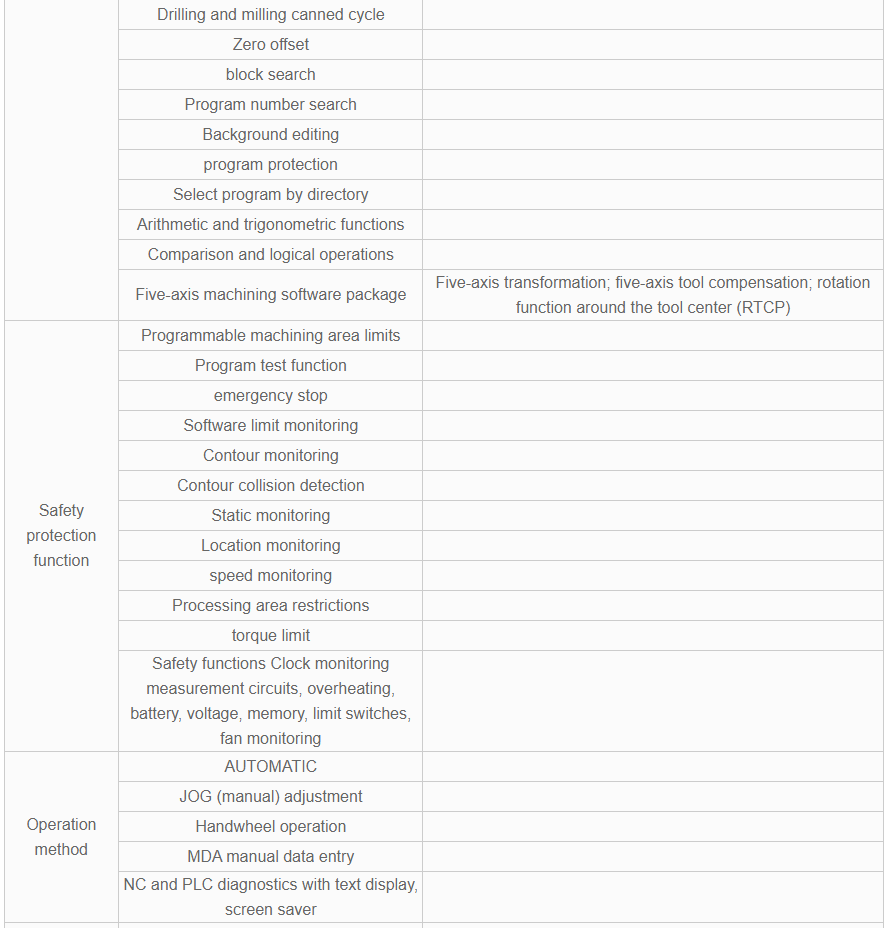

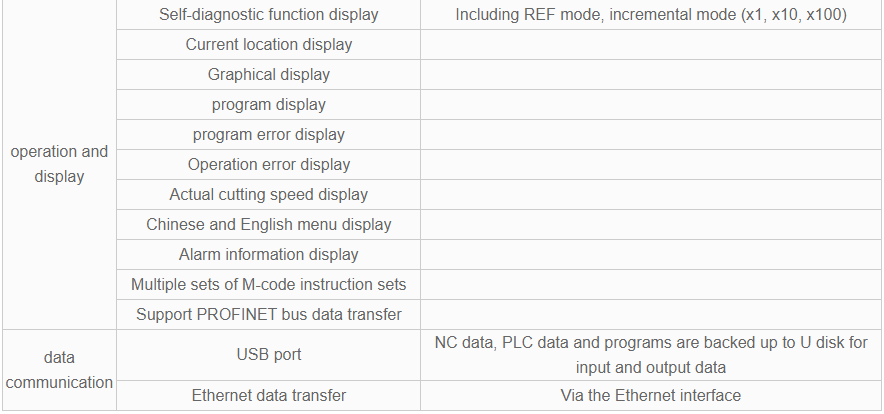

15. Function introduction of CNC system

Siemens 840Dsl.730 CNC system configuration

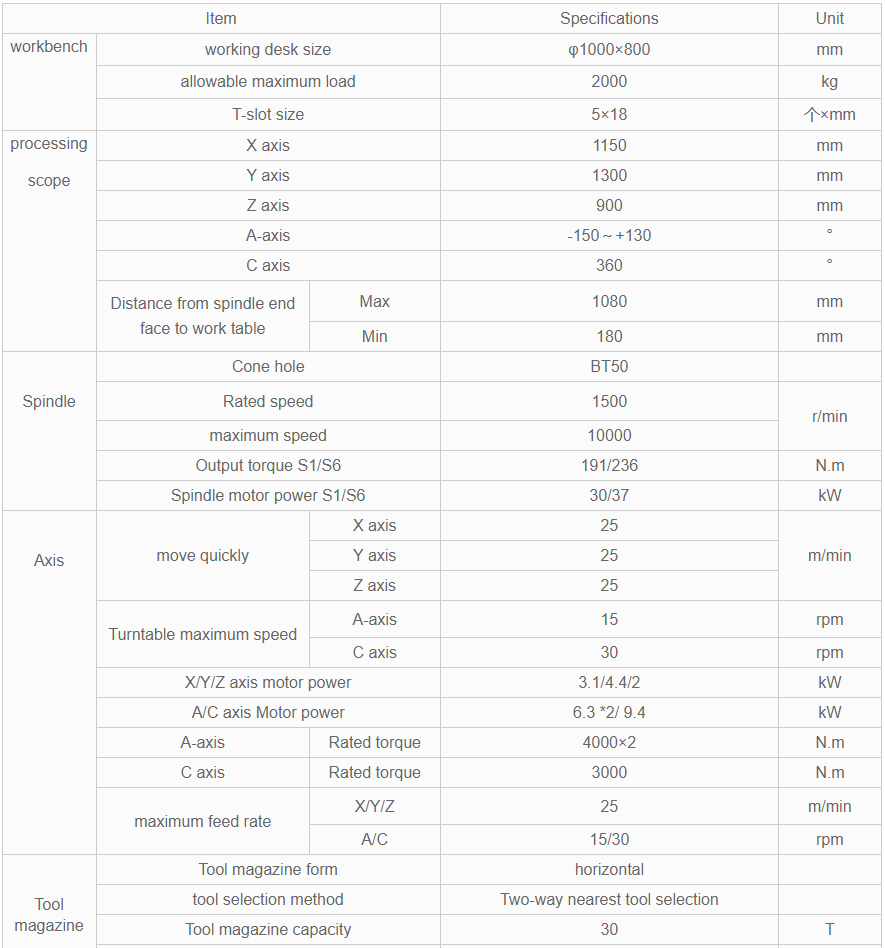

Main parameters:

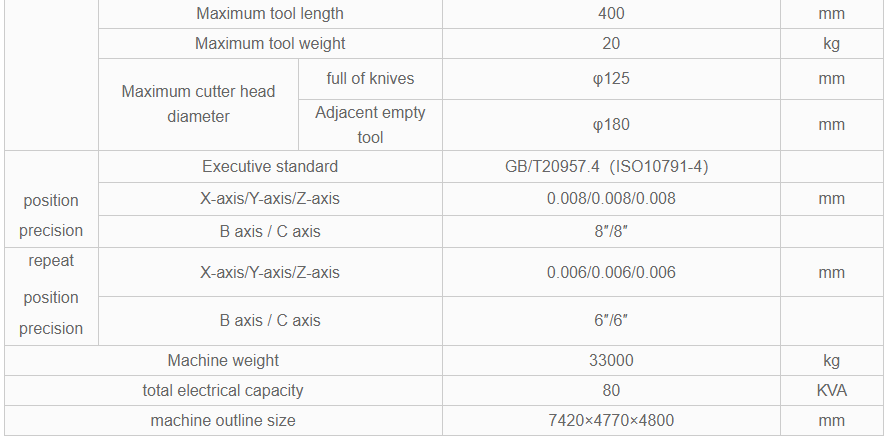

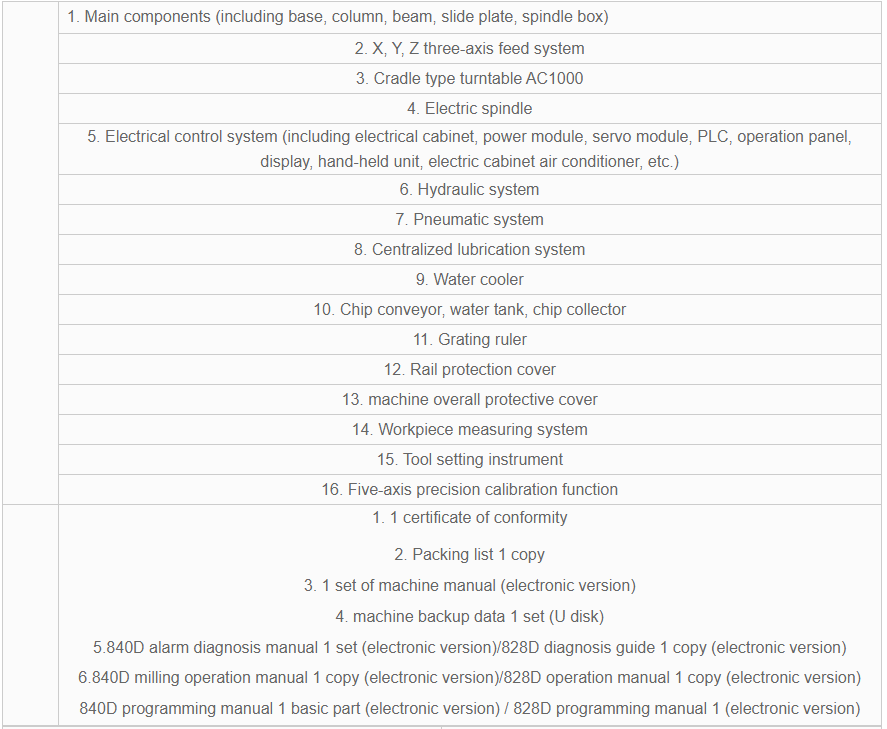

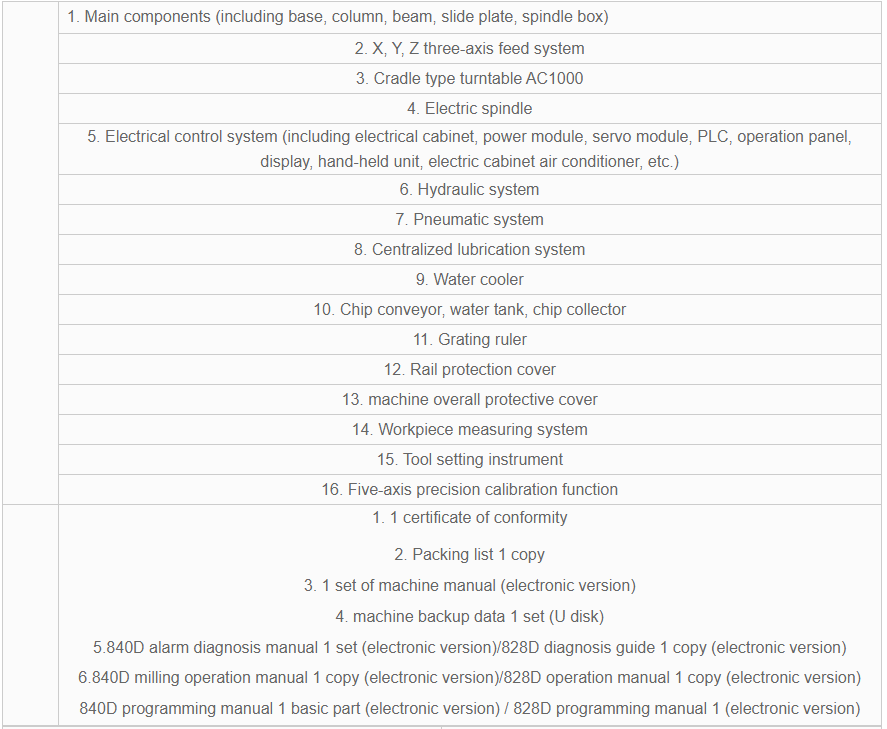

Standard configuration list:

|

The OM – 1000 five-axis machining center adopts a stable gantry structure, the column is fixed on the base, the beam moves longitudinally along the column (Y direction), the slide plate moves laterally along the beam (X direction), and the headstock moves vertically along the slide plate (Z direction). The workbench adopts the self-developed direct-drive cradle structure, and various performance indicators have reached the international advanced level.

The OM – 1000 five-axis machining center adopts a stable gantry structure, the column is fixed on the base, the beam moves longitudinally along the column (Y direction), the slide plate moves laterally along the beam (X direction), and the headstock moves vertically along the slide plate (Z direction). The workbench adopts the self-developed direct-drive cradle structure, and various performance indicators have reached the international advanced level.